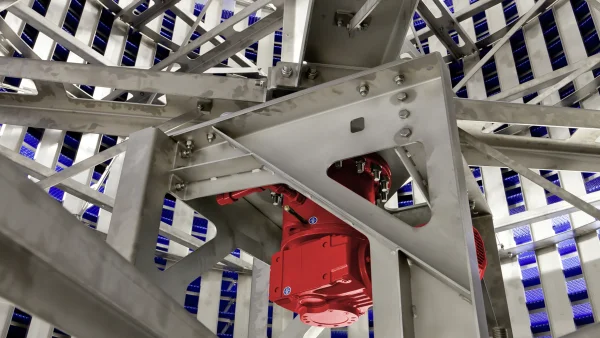

Spiral freezers are versatile systems used to cool and freeze products in the food and beverage industry. Due to the large temperature range and high mechanical loads involved in their operation, the components of these systems need to be highly durable. Our industrial gear unit solution is perfect for use in these conditions.

Robust, powerful drive solution for high thermal and mechanical loads

Complete solution from a single source

From breakfast rolls and frozen pizza to meat, fish and even ice cream: spiral freezers allow delicious food to be frozen as quickly, evenly and with as little damage as possible. The regulations placed on the food and beverage industry are extremely strict. As such, the challenges facing the designers of the drive technology are incredibly demanding.

The coatings used must not be susceptible to damage in harsh conditions, the gear unit bearings must be reinforced and the food-grade oil used for the gear oil should be as easy as possible to change.

Last but not least, the large range of temperatures encountered in such systems also needs to be taken into account. During freezing, temperatures can drop to -35°C. In addition to this, the system components – and thus the drive technology – also need to be able to handle temperatures in excess of 30°C without any problem during cleaning.

From breakfast rolls and frozen pizza to meat, fish and even ice cream: spiral freezers allow delicious food to be frozen as quickly, evenly and with as little damage as possible. The regulations placed on the food and beverage industry are extremely strict. As such, the challenges facing the designers of the drive technology are incredibly demanding.

The coatings used must not be susceptible to damage in harsh conditions, the gear unit bearings must be reinforced and the food-grade oil used for the gear oil should be as easy as possible to change.

Last but not least, the large range of temperatures encountered in such systems also needs to be taken into account. During freezing, temperatures can drop to -35°C. In addition to this, the system components – and thus the drive technology – also need to be able to handle temperatures in excess of 30°C without any problem during cleaning.

Complete solution from a single source

In addition to the outstanding drive component features, users also benefit from the fact that we provide complete solutions from a single source: from initial planning and configuring to starting up and maintaining the industrial gear unit solution. Short delivery times, high product availability and great service network coverage also add to the benefits we offer our customers.

Get in touch with us.

Your benefits

-

Robust from -35°C to +30°C

thanks to a cold and heat-resistant gear unit coating. -

Heavy-duty

thanks to the specially reinforced gear unit bearings, which act as locating bearings and can bear the full load of the drum. -

High power transmission

thanks to the large 630 kNm torque, which moves the spiral freezer powerfully at low speed. -

Global application expertise

thanks to our many years of experience in implementing tried-and-tested drive solutions for various applications in a wide range of ind

Features, options, areas of application and technical data for spiral freezer drive solutions

Features

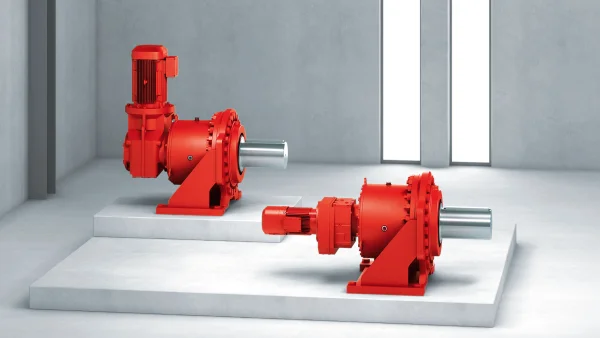

P.. series planetary gearmotors:

- Available in 11 sizes to match the size of the system

- Can transmit a high torque of 25 to 650 kNm

- Save space with their impressive compactness

- Offer a high degree of torsional rigidity

- Allow you to monitor oil temperature

Standard helical-bevel gear units as primary gear units

- Offer great versatility at the input end

- Are available for a large range of gear ratios

Areas of application

For use in spiral freezers in the food and beverage industry for deep-freezing:

- Bread

- Pastries

- Pizza

- Meat

- Fish

- Ice cream