Tunnel boring machines dig through various soil and rock layers and materials during tunnel and road construction. Our high-torque industrial gear unit combinations provide the necessary power.

Reliability in tunnel construction – thanks to powerful industrial gear unit solutions

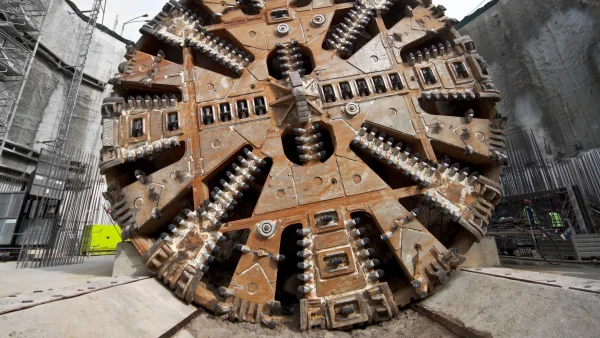

Modern tunnel boring machines consist of a rotating drill head followed by a main bearing and a propulsion system with downstream safety systems. The selection and the type of tunnel boring machine also depends on the geological conditions and the amount of groundwater present. The combination of durable bevel-helical gear units from the X series industrial gear unit and the P series planetary gear units are the optimal drive solution for every type of tunnel boring machine, regardless of how harsh the ambient conditions are. The huge range of available accessories and options reliably meet all your tunnel boring machine drive requirements.

Robust, powerful and durable: our drive system for cutting rings and drill heads

The cutting ring or drill head on the tunneling machine generally has a circular drive: several pinions are installed on the circumference of the circular main bearing with internal gearing, which are hydraulically or electrically driven by planetary and bevel-helical gear units. Slip clutches with a slip monitoring system are also located between the motors and the gear units. This prevents the entire drive system from overloading if the cutting head becomes blocked.

This solid mechanical engineering technology requires industrial gear unit solutions that are just as solid and reliable. All of the components in our drive system have been built to withstand the challenging operating conditions. Our efficient cooling concept for tunnel boring machines ensures a high level of reliability and the long service life of your system - and you also save on the need for external cooling units and a larger gear unit.

Get in touch with us.

Your benefits

-

Tailored solutions

thanks to perfectly compatible and proven components for the industrial gear unit combination to meet your needs. -

High operating reliability

thanks to our efficient cooling concept that ensures the reliability of your system. -

High power transmission

thanks to the high torque in a compact housing with robust technology.

Features and areas of application of drive solutions for tunnel boring machines

Features

- A combination of P series planetary gear units and X series bevel-helical gear units with special, horizontal cast housing with a larger surface area for better heat dissipation

- Efficient fan concept (axial fan)

- Splash lubrication or pressure lubrication with shaft end pump

- Efficient sealing system (taconite)

- Swing base and base frame

- Oil dip stick and oil level display

- PT100 oil bath temperature sensor

- Mechanical couplings / hydraulic couplings

- ATEX design on request

Areas of application

- Tunnel excavation

- Road excavation